In today's fast-paced world, where time is precious, technology is king, and health is paramount, the concept of intelligent household sterilizer cabinets is making a significant impact. These innovative appliances combine convenience and hygiene, and they are the products of dedicated factories committed to delivering safe, efficient, and intelligent solutions for the modern home. In this article, we'll explore the fascinating world of intelligent household sterilizer cabinet factories, their significance, and how they are shaping the way we maintain a clean and healthy living environment.

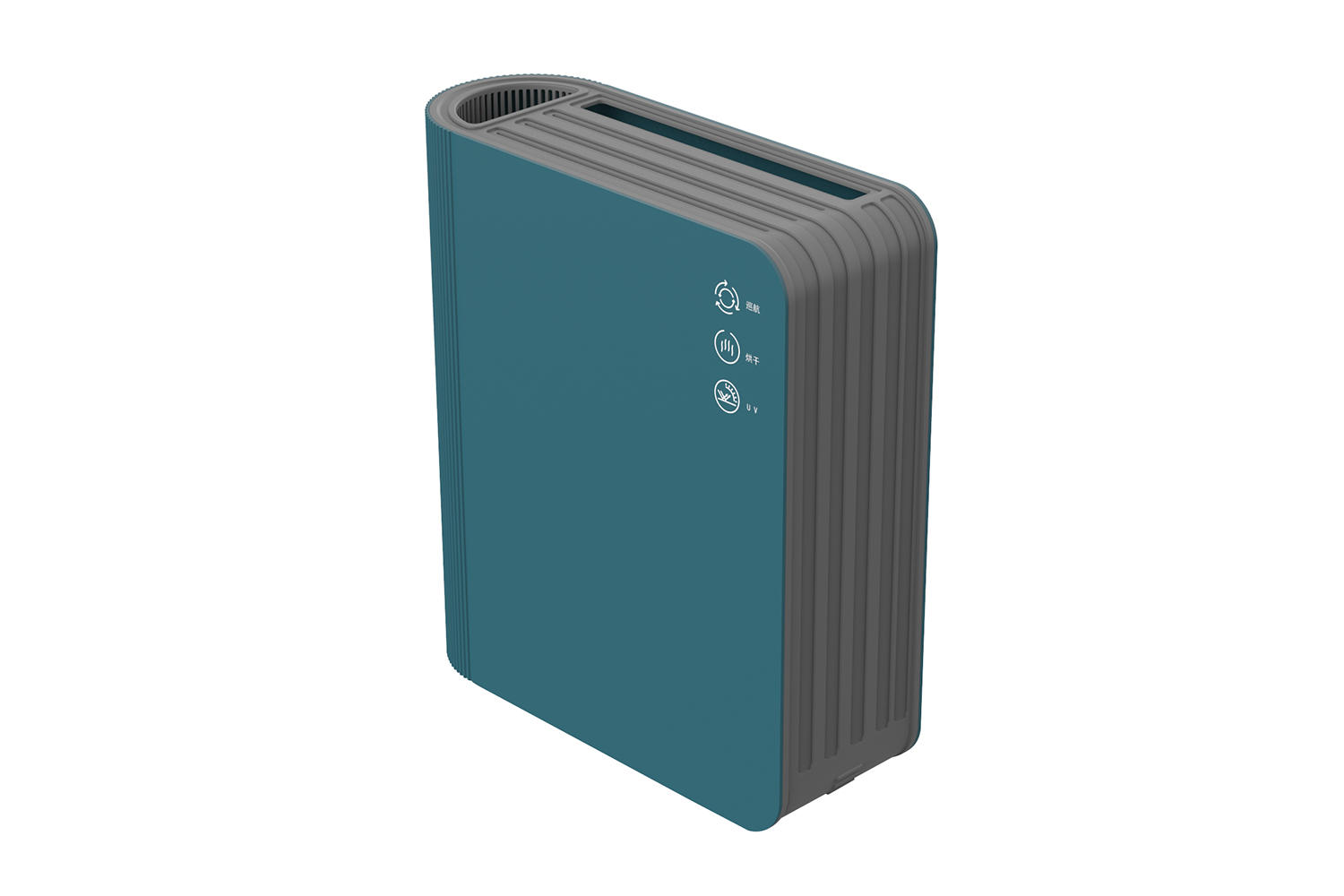

Intelligent household sterilizer cabinets are a testament to the fusion of technology and health-conscious living. These cabinets not only store and disinfect various household items, such as cutlery, baby bottles, and personal accessories, but they also bring a new level of convenience and safety to our daily lives. The factories that produce these cabinets play a pivotal role in making this transformation a reality.

These factories are responsible for designing, manufacturing, and quality-controlling these advanced appliances. They integrate cutting-edge technologies, including UV-C sterilization, ozone purification, and intelligent sensors, to create products that effectively eliminate harmful bacteria, viruses, and other pathogens. As a result, these cabinets contribute to a healthier living environment, particularly in households with children, the elderly, or individuals with compromised immune systems.

The manufacturing process of intelligent household sterilizer cabinets is a complex and highly specialized one. It involves several crucial stages:

Design and Engineering: The process begins with the design and engineering of the cabinet. This includes determining the optimal size, layout, and materials, as well as the integration of sterilization technologies and sensors.

Component Sourcing: Factories source high-quality components, such as UV-C lamps, sensors, and control systems, to ensure the performance and reliability of the cabinets.

Assembly: Skilled workers assemble the cabinets, ensuring that all components are correctly integrated, and that the electrical and electronic systems are well-connected.

Quality Control: Rigorous quality control measures are in place to test the cabinets' functionality, safety, and sterilization efficiency. Any defects are addressed and rectified at this stage.

Packaging and Distribution: Once the cabinets pass quality control, they are packaged for distribution to retailers and consumers.